Military Overspending is Common and Avoidable

Back in the 90s, the United States military conceived of an ambitious project to phase out its existing combat aircraft in favor of a new fighter jet that would be able to meet the needs of the Air Force, the Marine Corps, and the Navy[1]. This required the new line of F-35 jets to synthesize a wide range of needs specific to each branch of the military. It was decided that three slightly differing models of the jet would be created, with the hope that slight modifications of the basic model would be all that was required to fit it to the differing specifications.

Things did not go as planned. The initial weight estimates from their first model proved to be incorrect when fitted to the next model, necessitating an entire redesign accompanied by a huge delay. Production of the jets began before they were fully developed, resulting in the rollout of F-35s prone to technical malfunctions needing to be addressed by near-continuous retrofitting. The program stretched on for decades and ran far over budget with persistent technical errors and little to show for it in terms of useable aircraft.

The jets were finally deemed operational in 2019, but technical errors persisted and as recently as 2020, another plane crash caused by technical malfunction resulted in the further grounding of F-35s[2]. As of last year, only around half of the Pentagon’s F-35 fleet was considered ready for combat[3]. This is more than two decades after the commencement of the project with hundreds of billions of dollars invested.

Military projects have an enormous scope in terms of deliverances, money involved, and years of commitment tied up in the project. Such projects typically involve many milestones whose success is dependent upon a variety of departments and manufacturers. Mistakes are all too easy to make with this sort of project architecture, and the results of these mistakes are hugely magnified because of the large sums of money involved, with consequences felt for decades because of the timescale of the project. Money and resources are frequently squandered in these situations due to poor planning and execution.

Stories like this are far from uncommon. For additional examples, look no further than the UK’s Ajax armored tanks[4] or Australia’s MRH-90 helicopters[5]. The problems faced by these programs manifest themselves in the form of production delays, overextension of planned budgets, and the presence of technical errors in the eventual product. Australia’s navy already has a shaky history given the problems that have plagued their Collins submarine[6], and now they are on a trajectory to make the same mistake again with the Hunter class frigates they have ordered. The project has already been plagued by delays and gone far over budget[7].

These are no small hiccups—we’re talking financial losses in the billions due to poorly implemented technology solutions. These are losses that could have been avoided entirely if the right tools for the job had been chosen from the beginning.

One problem frequently contributing to these issues is a lack of coordination between the specialists responsible for implementing different parts of the task. The documentation surrounding a project like this can number in the thousands, and no single person working on the project will have read through it all. The documentation surrounding the Hunter frigates already exceeds 730,000 documents. The specifications for the undercarriage alone of the F-35s are over 3,000 pages. Further compounding the problem, the execution of those instructions may be split between different departments. Given that the documents will reference and depend upon one another, the segmentation of knowledge surrounding a project like this is a disaster waiting to happen (and as often as not, it does).

The money currently being wasted on these projects is a way of buying familiarity, of putting a representation of the problem in the Unconscious Mind of the people involved, of learning the connections among all the pieces. If there is no other way of doing it, spending lots of money is the only way – seen in that light, the money is not wasted, but necessary. Our product offers another way of building a complex representation the way termites build a mound – little by little. With our approach, the “words on a page” become an abstract structure which can be viewed in fine detail locally or seen overall.

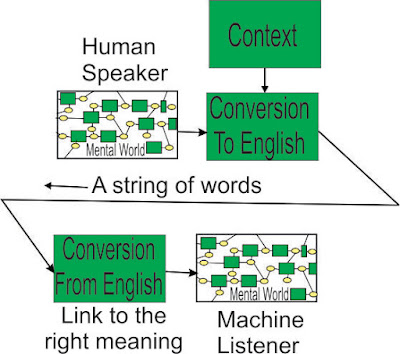

Imagine a technology that could sift through all of the documentation surrounding a project of this scale, map out how those documents relate to each other, and track all of the variables associated with these documents, communicating them between specialists and tracking what has been done and what still needs doing. Imagine a technology that could translate the specialized language of a technical document into a more accessible form for users from a different field, summarizing the key points for them.

Our ground-breaking new technology, Active Structure, does just this and so much more. Unlike the large language models so prominent in the media right now, our technology truly understands the meaning of the texts it interacts with. This is because the relational networks it creates when mapping out a text are grounded in the actual meanings of the words involved, rather than abstract quantifications of words translated into node weightings. An added benefit of this method is greater model transparency that even a non-expert can interpret. If you’re planning a complex project and looking for a way to safeguard it from becoming a financial disaster, look no further than our product.

[3]https://www.bloomberg.com/news/articles/2023-03-29/pentagon-says-only-half-of-its-f-35-jet-fleet-is-mission-ready

[4]https://www.civilserviceworld.com/in-depth/article/ajax-mod-programme-far-from-on-track-gduk-contractor-claims-mark-francois

[5]https://www.theguardian.com/australia-news/2023/jan/18/sting-in-the-tail-why-australias-taipan-helicopter-purchase-was-a-debacle-from-the-start

Comments

Post a Comment